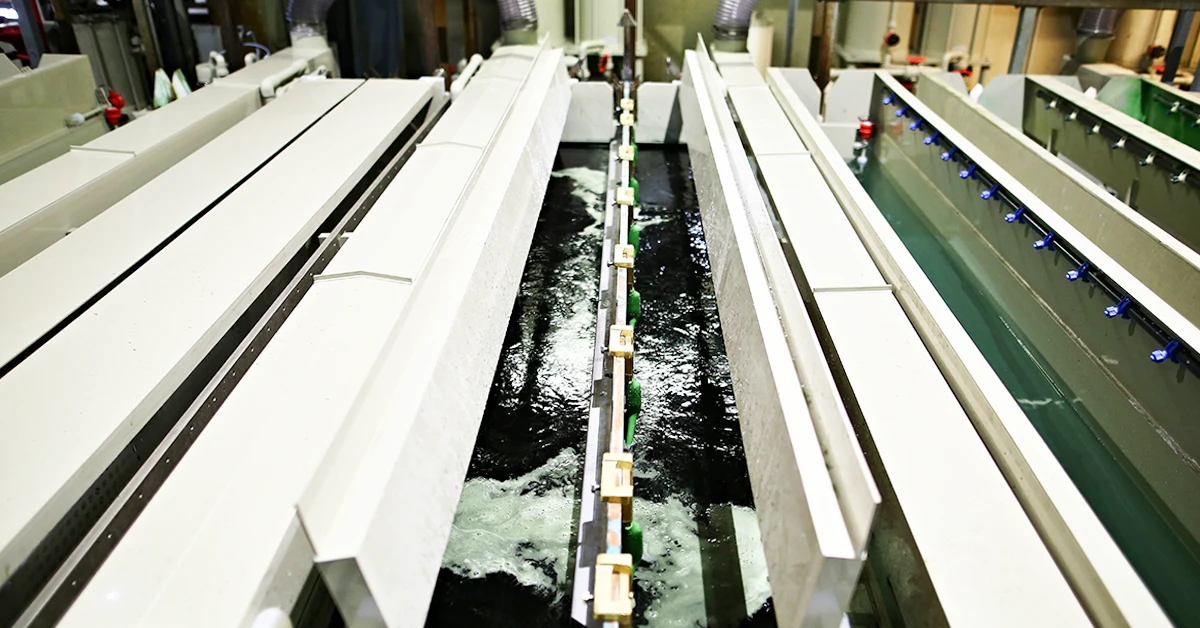

We are thrilled to announce the opening of our new production line that focuses on galvanic plating of plastics without the use of hexavalent chromium. This innovative technology brings a range of benefits not only for our company but also for the environment.

New production line for eco-friendly galvanic plating of plastics

Traditional methods of galvanic plating of plastics often involve the use of hexavalent chromium, a substance known for its toxicity and negative impact on the environment. Aware of the ecological challenges, we have decided to invest in a modern process that eliminates the use of this harmful element.

The key advantages of our new hexavalent chromium-free technology include:

1. Environmental protection

Eliminating hexavalent chromium from the production process reduces negative impacts on soil, water, and air, contributing to the protection of biodiversity and the sustainability of our planet.

2. Degradation of dangerous substances

Hexavalent chromium is one of the dangerous substances that can pose a threat to human health if mishandled. Our new technology provides a safer environment for workers and potential product users.

3. Energy efficiency

Modern procedures employ more efficient methods, leading to a reduction in the overall energy consumption of the process. This not only conserves resources but also lowers greenhouse gas emissions.

4. Quality results

Our new technology delivers excellent results in the galvanic plating of plastics, ensuring products with high durability and aesthetic quality.

By opening this production line, we not only innovate our manufacturing process but also contribute to global efforts toward sustainable development. We believe that our investment in eco-friendly galvanic plating of plastics without hexavalent chromium represents a step in the right direction, and we take pride in playing our part in safeguarding our planet.

Thank you for your support, and we look forward to the journey towards a more sustainable future.